PVC Pipe Offers Reliability Wrapped in Sustainability

From Canada to South Africa, PVC is increasingly becoming the pipe material of choice for water infrastructure. Here in the U.S. too.

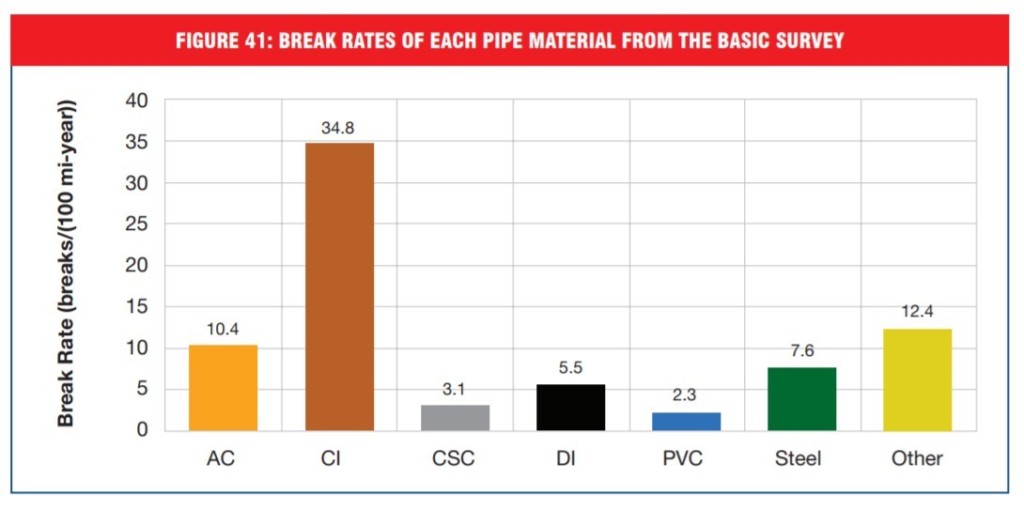

There’s a good reason for this, and it starts with a simple but important factor: reliability. According to a 2018 study by Utah State University, water main breaks from PVC pipes were the lowest among commonly used pipe materials. This is significant when you consider that there are approximately 1,000 water main breaks a day in the United States alone.

Municipalities are looking for options. Often they’re turning to PVC.

From Water Main Breaks in the U.S. and Canada: A Comprehensive Study.

2 key reasons PVC pipe is so reliable.

Two factors are key to PVC’s reliability: flexibility and immunity to corrosion. PVC pipe is flexible. It’s more elastic than other pipe materials so it can tolerate both pressure and water pressure surges. Its flexibility also means that a PVC pipe buried in the ground can tolerate temperature changes, adapting to the cold and bouncing back as temperatures rise (versus, for example, the impact of cold on concrete and iron). Couple that with PVC’s immunity to rust and corrosion and you start to understand why PVC pipe has a life span of well over 100 years.

In addition to its reliability, PVC is portable and easy to handle. This matters everywhere, but especially in parts of the world where heavy equipment might be lacking and people are digging trenches with shovels and other hand-held tools. That’s one reason Water Engineers for the Americas chose PVC pipe for its clean water project in remote villages in Honduras. That’s why PVC pipe is in use more and more for water and sanitation projects across Africa. In South Africa, for example, 99 percent of the water main pipes are PVC pipes.

Because PVC pipe is so lightweight, it’s also efficient to ship. Plus, pipes of smaller diameter can be nested into larger pipes, so that you can ship much more in one truck, train, or shipload than you could, for example, concrete or iron pipes. This translates into a lower energy footprint—and a more sustainable product.

Here’s why PVC pipe is the sustainable choice.

“The only reason to have a water main pipe is to get clean water to your home,” said Ves Sobot, director of corporate affairs for Vinyl Sustainability Council member IPEX Management Group. “And the fewer breaks, the cleaner the water.”

The fact is that PVC pipes save on energy use in multiple ways. In addition to their weight and nesting properties, the same smoothness that eases movement of water through the pipes also makes that movement happen efficiently. That can translate into significant energy savings, which is good for the environment.

Here’s another reason this matters: About 7 percent of all the electricity consumed by a city goes to pump water. Less electricity to pump water? More cost savings.

A smart choice backed by innovation.

Sobot said that “vinyl represents innovation,” and he shared an example from another use for PVC pipes: wiring. PVC pipe is non-conductive so that it’s an ideal material for housing wiring. Sobot pointed out that, in the early 20th century, ships were constantly battling electrical fires. During World War II, however, the U.S. ripped out all the old wiring on its ships and submarines and replaced it with PVC sheathing in PVC conduit pipes. Innovation—and lives saved. Today, you can see that same philosophy at work in the PVC wire-casing pipes in the basement of the U.S. Capitol.