Top Three Sustainability Takeaways from Greenbuild 2019

In November, I, along with several Vinyl Institute staff headed to Atlanta for Greenbuild, the largest green building show worldwide. This is one of my favorite shows to attend each year because it really helps foster the opportunity for collaboration and meet people across a wide variety of industries.

It was a busy four days attending a variety of sessions, participating on several panels, including a session on embodied carbon. I left with some great takeaways that I’m excited to share.

Circularity

The circular economy concept has been around for years, and circularity continues to be a major theme in the sustainability discussion, but I saw more focus on the resilience of products. I heard plenty at Greenbuild about recycling and what happens at end of life, but also how we can prolong material service life so products last longer and how we can design and develop products and materials that really are performance-based and resilient when factoring in what is happening with global warming and climate change.

Resilience could be considered the ultimate measure of sustainability—providing safer and higher performance products and buildings that reduce human loss.

Material Science

During the conference it was apparent that we all need to do a better job of connecting the design community with material science information. People are selecting materials on a single attribute versus a life cycle basis. Doing so has demonstrated unintended consequences of premature product and material failure. We should be looking at the chemistry and life cycle of materials and products within the context of use and for appropriate application.

Single attribute approaches, including red listing of chemicals without evaluating the chemistry and utilization of chemicals within a formulation leads to potential product failures and possible increased impacts to the physical environment and human health. In using a life cycle approach, all aspects of a product are reviewed in context of the required performance, durability, maintenance, and building/product service life.

Unfortunately, there have been substantial failures of products within healthcare systems that use a “perceived” better choice for upholstery that has subsequently led to rolling failures that are anticipated to reach over $100 million. These choices were made based upon non-science-based approaches that did not use sustainability criteria in conjunction with the performance and cleaning/disinfection needs of a product in a healthcare setting. There is a gap in understanding of the need to select materials based upon science versus activist rhetoric to avoid these types of failures. There needs to be a better, more comprehensive way to educate the design community about material health as it relates to risk and exposure and material science and how products are formulated.

Reflecting on this takeaway from Greenbuild makes me appreciate the establishment of the interdisciplinary Durable Coated Fabrics Task Group, as it has provided a unique opportunity to bring together voices of different organizations and disciplines to educate stakeholders on factual information – evaluating product from not only a hazard perspective, but also from an exposure and risk perspective in context with required performance characteristics.

Embodied Carbon

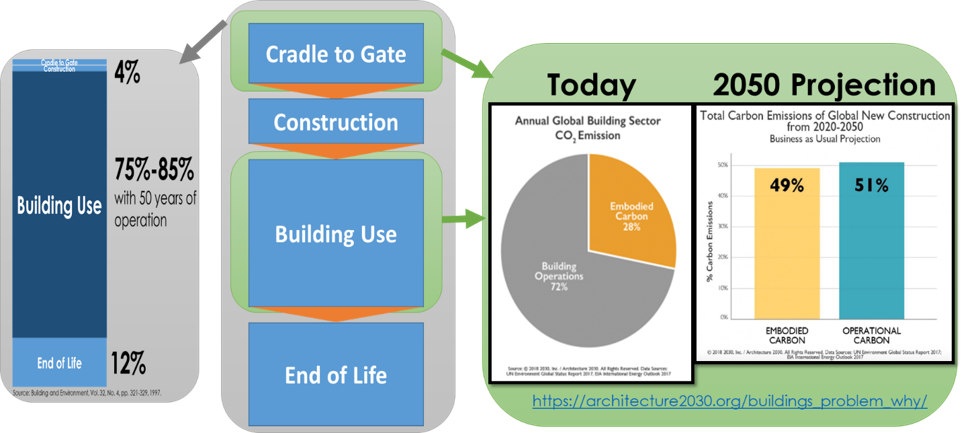

Embodied carbon was the major topic this year at Greenbuild. When it comes to building and construction projects, there are two types of carbon evaluated: embodied carbon and operational carbon. Operational carbon considers how many greenhouse gases (GHGs) are released during the useful life of a building, while embodied carbon considers the amount of GHGs that are released during the life cycle of a product.

Carbon emissions are important because in 2017, carbon dioxide made up 82 percent of all GHG emissions in the U.S., and while currently most of these emissions are coming from operational carbon, in the next 40 years that will change to embodied carbon.

The diagram below is from the “Fake News: Busting the Myth of Embodied Carbon” presented by Ben Meyer (GAF), Dr. Michal Porter (Dupont), and myself.

The Carbon Leadership Forum launched the Embodied Carbon in Construction Calculator (EC3) tool that will allow architects, designers, and engineers to estimate embodied carbon of products specified in the design phase.

It’s important to remember that this is only one component of the evaluation, as operational carbon also needs to be evaluated during the building use phase. As I mentioned above, selecting products only based upon the single attribute, in this case, embodied carbon, can lead to unintended consequences and potential premature product failure. Similar to evaluating a product by any single attribute, such as recycled or bio-based content, embodied carbon should be evaluated as a part of the product selection decision process, but not in lieu of performance, durability, cleanability, and building service life requirements established by the Owner Project Requirements (aka Operator Program Requirements).

It is exciting to see how the vinyl industry and the building product marketplace progresses over time for continual improvement in all aspects of sustainable practices – focusing on all aspects of product development through the lens of life cycle assessment.