Advancing Circularity in the Vinyl Industry

The Vinyl Institute (VI) and the Vinyl Sustainability Council (VSC) support the transition from a traditional linear economy (make, use, dispose) to a circular one (make, use, recycle). Our members are committed to the responsible use of natural resources and extending the use of these materials through reuse, repurposing, recycling, and recovering the value locked inside vinyl materials traditionally viewed as waste.

- designing responsibly

- using pre- and post-consumer vinyl materials as a resource

- recycling and recovery

- enabling greater service life

Designing Responsibly

We are committed to using responsibly sourced raw materials, employing advanced manufacturing technology, and designing products that can be reused, repurposed, and recycled to reduce environmental impacts.

- Continuous improvements in vinyl manufacturing technology have reduced VCM and dioxin emissions for more than 40 years.

- Salt, the primary raw material used to manufacture vinyl, reduces the amount of fossil fuels used resulting in a comparably lower carbon footprint for vinyl products.

- Continuous improvements in vinyl product manufacturing efficiency is resulting in less internally generated scrap.

- More recycled content in product design is being encouraged by the vinyl industry.

- Vinyl products leverage unique material attributes that help reduce operational carbon – including thermal efficiency, flexibility, flame resistance, and durability. For example:

Reduced energy consumption

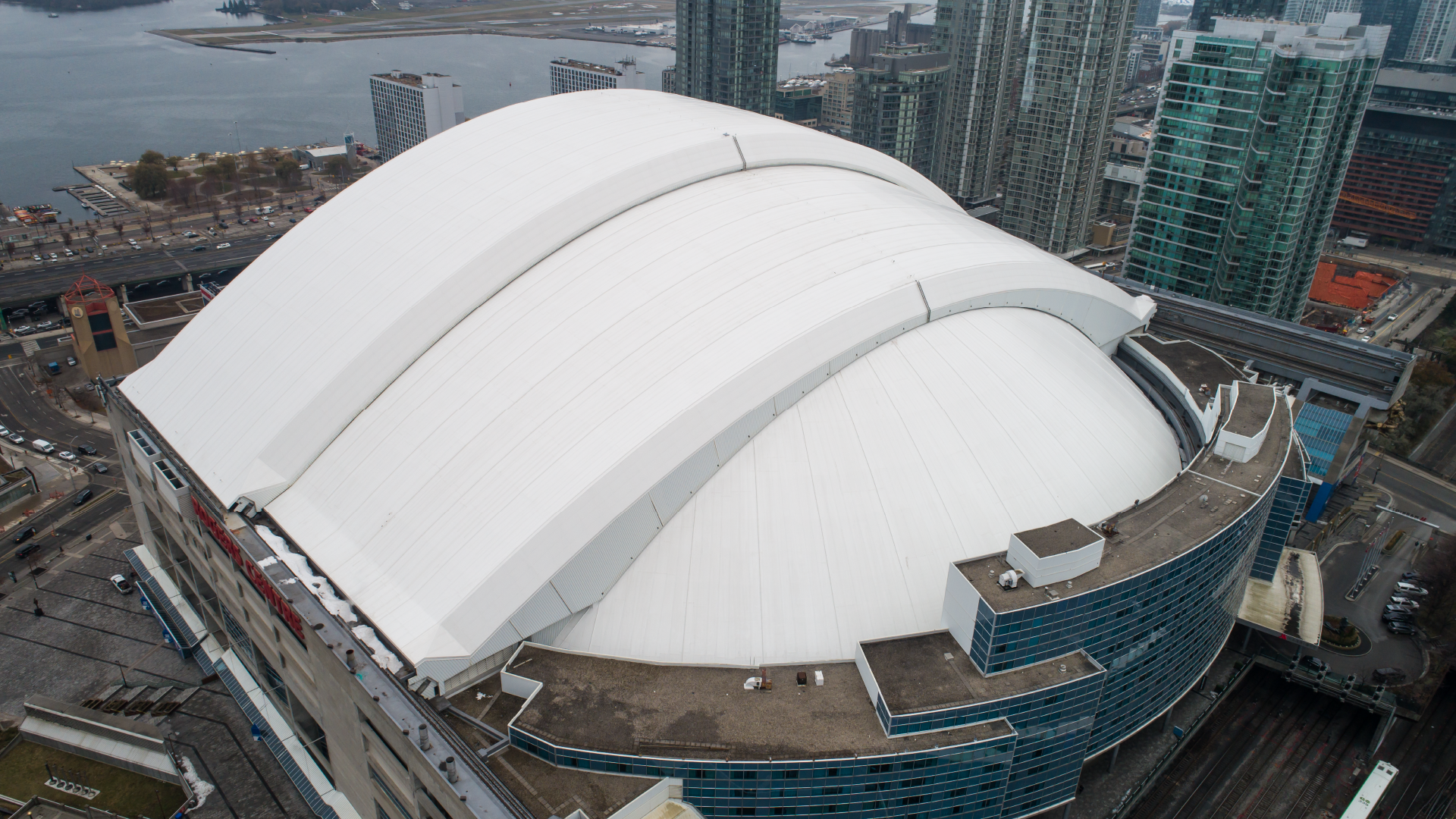

Energy efficient, white vinyl roofs reflect solar energy from the sun to keep buildings cooler and reduce energy consumption.

Lightweight

Lightweight vinyl products are easier to move, reducing carbon from shipping to installation.

Flame resistant

Inherent flame resistance of vinyl makes it optimal for indoor sprinkler systems and wire jacketing for electrical systems.

Smooth surface

Smooth interior of PVC pipes reduces energy required to pump fluid through piping systems.

Energy efficient

Energy efficient vinyl siding improves the insulation of buildings and reduces the heating and cooling energy demands.

Non-porous

Smooth and non-porous surfaces of vinyl flooring and wallcoverings allow for easy cleaning and disinfection.

Using Pre- and Post-consumer Vinyl Materials as a Resource

We focus on reducing waste by using more recycled content in products and improving manufacturing processes.

- More than 1 billion pounds of vinyl is recycled annually in the U.S. and Canada which includes 958 million pounds of pre-consumer vinyl materials and 142 million post-consumer vinyl materials.

- Pre-consumer vinyl materials or scrap is a highly desirable resource because it easily incorporates back into a manufacturing process.

- Scrap from vinyl products, like window profiles and pipe, can be recycled back into the same product multiple times without compromising performance.

Recycling & Recovery

We encourage and support recycling and recovery of vinyl products that have served their original usefulness.

Our goal is to increase post-consumer vinyl recycling by 15 million pounds by 2025.

Today, 142 million pounds of post-consumer vinyl materials are diverted from landfills annually in the U.S. and Canada. Examples of industry recycling and recovery efforts include:

Industry led recycling pilot projects for roofing and vinyl siding.

Vinyl roofing membranes are recycled back into new roofing and other construction products.

Vinyl billboards are reused as large tarps and tents, and even shelters for refugees.

Vinyl flooring is recycled into new flooring and other products.

Vinyl siding is remanufactured into siding, fencing and decking products.

A variety of recycled vinyl materials are remanufactured into shipping pallets, highway sound barriers, garden products (hoses) and automotive fill.

Enabling Greater Use

Vinyl product manufacturers make products that are durable and resilient which extend usefulness. The durability and resiliency of vinyl infrastructure products keep the demand for replacement materials low and reduce the burden on recycling systems and the need for raw materials.